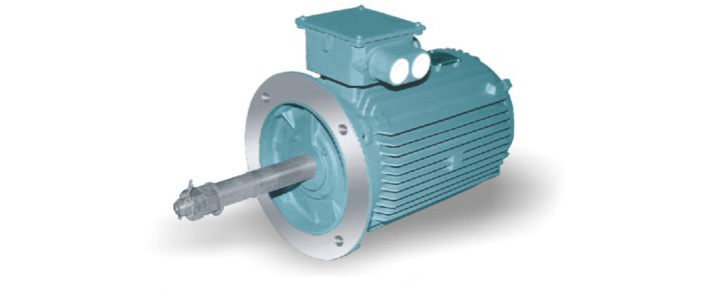

Cooling Tower Motors

OSWAL Induction Motors for various industrial application like Machine tools, Textiles, Air Conditioning, Dairy OSWAL Cooling Tower Motors are the products of the expertise of highly qualified technical team with a stage wise rigid inspection method under TQM concept.

Salient Feature :

The Motors are rugged in construction and are designed for satisfactory operation at wide voltage fluctuations.

Special care is taken in design for Cooling Tower application.

Higher efficiency and power factor ensuring lower power consumption and lower operating temperature of the motor.

Motors with Ip55 degree of protection and class ‘F’ insulation.

Shaft extension as per customer requirement (can be provided with lock nuts).

Rotors used are pressure die cast and dynamically balanced.

Connections are made by electric brazing to eliminate loose connection.

Winding is varnished using vacuum impregnation and treated for protection against humid atmosphere.

Bearings are shrunk fit in bearing seats which are ground to close tolerances.

Mounting : V1 (Shaft downward position)

Relative Humidity : 90 %

Flange : B- as per IS - 2223

Shaft can be supplied with stainless steel material AISI – 410 as per customer requirement.

| Specifications : | |

|---|---|

| Output | 0.093 - 90 K.W |

| RPM (Pole ) | 2, 4, 6, 8 & 10 Pole |

| Type | Three Phase Electric Motor |

| Enclosures | Totally Enclosed Fan Cooled / SPDP |

| Frames | 56 – 280 M |

| Ambient temperature / temperature rise | 45* C / 75* C, Class – B by resistance method |

| Insulation Class | ‘F’ |

| Voltage | 415 + 6% V |

| Frequency | 50 + 3% Hz |

| Combined Variation | 10 % (absolute sum) |

| Connection | Star up to 1.5 K.W / Delta above 1.5 K.W |

| Altitude | Up to 1000 meters above sea level |

| Duty | S1 |

| Degree of protection | IP-55 |

| Terminal Box | Top |

| Bearing | Anti frictional ball bearing |

| Grease | High temperature lithium complex grease (155* C) |

| Main Dimensions | Foot mounted according to IS: 1231 |

| Flange mounted according to IS: 2223 | |

| Foot cum Flange mounted | |

| Face Mounted | |