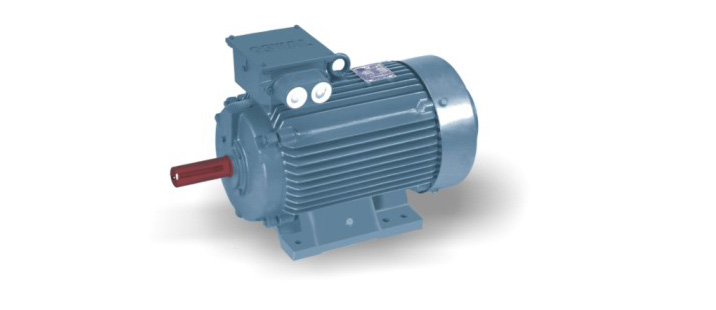

Thresher Electric Motor

OSWAL Thresher Electric Motor Induction Motors are for various industrial application like Machine tools, Textiles, Air Conditioning, Dairy Equipments, Crane & Hoist, Pollution control, Aquaculture & agriculture, Fertilizers, Mines & Chemicals Industry. The Range of products are standard motors, energy efficient motors, dual speed motors, cooling tower motors and other special motors designed as per customers specifications. The qualities of motors are excellent as it is manufactured under the supervision of a team of highly qualified, experienced & dedicated people of the organisation.

All motor shafts are of 40 C8 /EN-8 material. Motor shaft of AISI 304, 316, 431,410 & other material can be supplied on request. Shaft are having threaded centre hole for locking of pulley / gear from driving end. Motors are supplied with keys duly fitted on the shaft.

All standard motors are capable of service factor 1.1 at rated voltage & frequency / or continuous duty.

Rotors are of squirrel cage, aluminum die cast & are dynamically balanced with a half key to keep the vibration levels low. Motors with very low vibration

level requirement for machine tool application can be given on request. Core material is low loss high grade silicon steel.

All motors can withstand momentary overload of 1.6 times of rated torque, for 15 seconds without stalling.

All standard motors are having deep groove radial ball bearings '(Single row)'. Deep groove ball bearings are capable of taking axial loads in both the direction

in addition to the radial loads at high speed.

Oil seals are provided to ensure IP - 55 protections. The rubbing action on sealing surface prevents penetration of solid contaminants /moisture into the motor. The rubbing surfaces are with appropriate surface finish. Hence rise in temperature is minimum.

Noise levels of the motors are maintained as per specification in IS : 12065.

Motors are tested for vibration level of normal class as per IS : 12075. Precision levels of vibration can also be given on request.

Motors can withstand for starting up time 5 to 7 seconds for two starts from cold condition. For any other condition customer shall specify GD2 speed, period

of acceleration. Duty cycle, speed torque curve of driven equipment & method of starting.

Specification :

| THRESHER MOTOR |

| MODEL |

KW |

HP |

FRAME |

| OM-236 |

3.7 |

5 |

132S |

| OM-237 |

5.5 |

7.5 |

132M |

| OM-237A |

7.5 |

10 |

132M |

| OM-237B |

7.5 |

10 |

160M |

| Output |

3.7 KW – 7.5 KW / 5 HP – 10 HP |

| RPM (Pole ) |

1440 rpm / 4 Pole |

| Type |

Three Phase Squirrel Cage Induction Motor |

| Enclosures |

TEFC (Totally Enclosed Fan Cooled) |

| Frames |

132 S, 132 M & 160 M |

| Ambient temperature / temperature rise |

50 C / 60 above ambient temperature |

| Insulation Class |

‘A’ |

| Voltage |

415 + 6% |

| Frequency |

50 Hz + 3% |

| Connection |

Star / Delta |

| Altitude |

Up to 1000 m (above sea level) |

| Duty |

Continuous |

| Degree of protection |

IP-55 |

| Terminal Box |

Top |

| Bearing |

Deep Groove ball bearing (single row) |

| Grease |

High Temperature lithium complex grease (155 C) |

| Main Dimensions (mounting) |

Foot Mounted (B3) |